This article serves as the text version of our latest video. If you prefer to watch the video, see here:

Hello everyone and welcome to Twisted Fields, our research farm in San Gregorio California. we’re developing Acorn, our open source Precision Farming Rover. We believe that robots like this can help produce healthier food for all, reduce our reliance on harmful agricultural poisons, and fight climate change through regenerative agriculture.

In our last article we showed off several recent improvements we have made to our robot design and briefly mentioned our new crowd funding campaign.

In this post, I want to share more about our goals and motivations, and make the case for why you might want to help fund to our work. I’ll start with the background on who we are, show the work we have done so far, explain why we are choosing to raise funds this way, and how your monthly contributions can keep this project open and accessible to people all over the globe.

Before I get in to it, I’ll give you the short version of our pitch, and let you know where to make your tax deductible donation.

We’re designing a general purpose solar powered farming robot intended to be used for every step of the farming process in a regenerative organic farming system. This means preparing the soil, planting seeds and starts, pulling weeds, and even harvesting. This is a big job, and we don’t intend to solve it all ourselves. Instead we are taking a community oriented approach. Our machine design, software, and electronics are all open source. This means we share the design files and code, and allow anyone to produce their own machines with no restrictions. We will help build up a community of users all over the world, and through the innovation of the crowd we will lower the cost and ensure broad access to machines like this worldwide. We are finalizing a kit design now which we will sell at a fair price in the next year or two. To keep our system and our research open and accessible to all, we are building up a broad base of donors who can contribute on a one time or monthly basis to further our efforts. Donations are tax deductible and our funding campaign is easy to contribute to with just a few clicks. So if you’re already hooked, follow this link to our crowd funding page and make your contribution today.

We also invite you to subscribe to our youtube channel, or join this free community discussion forum right here at community.twistedfields.com. Now let’s get to full story.

This project is primarily the work of myself and Daniel Theobald. I’m a robotics engineer with plenty of industry and start-up experience, and Daniel is founder of Vecna Robotics, Mass Robotics, and this farm, Twisted Fields. Daniel and I have both been dreaming of farming robots for the better part of a decade. Around the time that I was writing short stories of automated farming communes, Daniel was applying for grants and looking for a property to start a research farm.

When Daniel and I met I shared with him a small book of my stories, and soon he’d invited me to his farm. We began to work together, and when I read one of his grant applications for a low cost precision farming rover accessible to people the world over, I knew I wanted to focus on that. And so, we did.

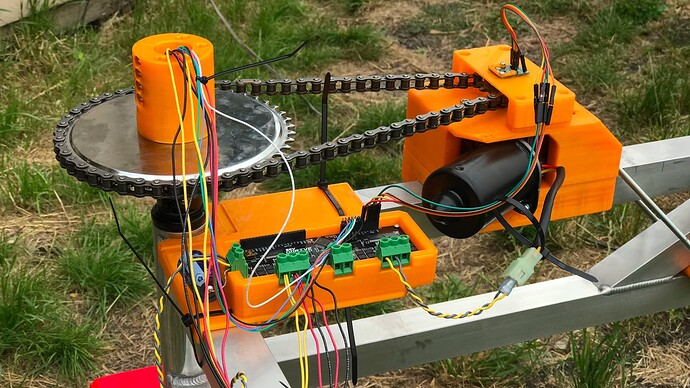

For three years we have been working to design and develop our robot. Key design decisions are: solar powered, four wheel drive and four wheel steering, lightweight, and something that can be built in a small shop in any city in the world.

We started with bicycle parts and 3D printing. We designed a simple rectangular frame made from welded aluminum and brought up drive and steering on all four corners. We got it driving under remote control, then added a small computer and GPS to make it self driving. We now have a solid prototype for a base vehicle that will soon carry tools and computer vision to work the soil and help grow our food.

In March 2021 we announced the project to the world, released all of our design files, began producing videos showing off our work, and opened our community forum so anyone could join and discuss our efforts.

The community is excited. Our videos and blog posts have been viewed over 50 thousand times. We have been featured on popular sites tech like Hackaday and Toms Hardware.

It is clear that people want a machine of their own. And so, that’s our next step. We are working on a production version of our robot. A kit people can build or buy to assemble their own vehicle. The first users of these machines will form a community of developers and prototypers who can help develop tools to use this new kind of farming platform.

Now at this point you might be asking, what exactly are we building, who is it for, what do we plan to do with it, and how is our approach different from other farming robot projects?

Acorn is a precision farming rover, or PFR, designed for regenerative agriculture at small to medium sized farms. Ultimately the machine will be comprised of three major components. The vehicle, which you see here, a crop vision system, and tools. The vision system and tools will be mounted in the large work bay underneath the vehicle.

We intend to build a system that can be used in the entire farming process, from soil preparation, planting seeds and seedlings, cover crop management, crop thinning, weed pulling, and harvesting.

Vehicles like this are new in the world of farming. The last century saw an expansion both in the size of farming machinery and the use of artificial fertilizers and biocides. Much can be said of this expansion, which led to an abundance of food as well as a degradation of our environment. Heavy diesel tractors compact the soil and emit greenhouse gasses. Fertilizers and poisons destroy soils and pollute waterways. Critical insect populations have been decimated. As we have pushed against the balance of nature, many have looked for other solutions.

Regenerative organic agriculture is one response to these issues. By going back to human scale farming, using smaller tools and organic inputs, we can manage healthier soils that naturally feed and protect plants from disease and pests.

At this smaller scale, the machines of the last century seem overbearing and clumsy. The most popular tools in regenerative organic are the hoe and the human hand. Generations of farmers the world over have proven the techniques, while young farmers and universities rediscover these methods anew.

This way of farming works well for its many practitioners, but requires much in the way of human labor. Food produced in this way is delicious and healthy. But with need for so much labor, how will we ever scale regenerative agriculture to produce enough for everyone?

This is where Daniel and I see opportunities. Robots are like labor in a bottle. Find a task well suited to automation and you can do it ten thousand times per day without ever breaking a sweat.

We wonder: what kind of a machine would work well to aid in human scale farming? Is it possible to work the fields with solar power alone? What existing methods can be adapted to this kind of machine, and what other techniques could be devised to accomplish the desired ends?

This is the focus of our research. We are designing the machine to aid in our work. But we know too, we cannot answer all of these questions alone. And so we are taking a community oriented approach to engineering development.

As I said, the final system will be the vehicle, tools, and a vision system. We are finalizing the vehicle design first. This automated self driving platform will be capable of driving itself around the farm and over the tops of the farming rows.

We will sell these vehicle kits to early adopters and universities who would like to collaborate with us on tool and vision research. Then, as a community, we will begin the difficult process of tool design and testing.

As our community grows and we begin to produce workable solutions, our system will have broader appeal. Everyone from established farmers to tech workers looking for a change in career might want one of these machines.

This open community-oriented approach sets us apart from most other farming robot projects out there. To explain why we think this is important, let me tell you a story.

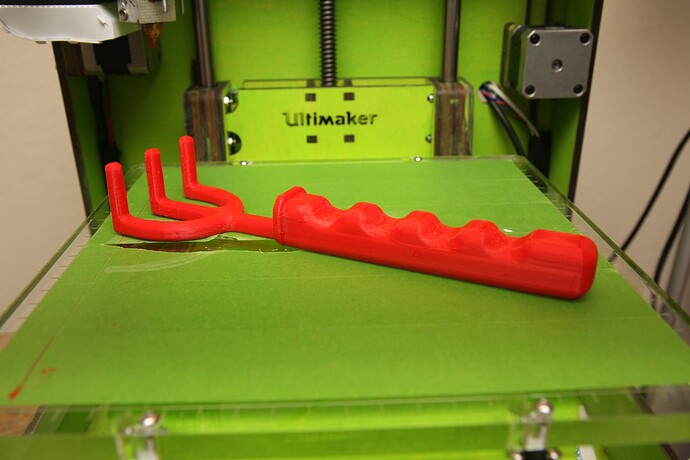

In college I studied Mechanical Engineering. In a class on materials and manufacturing methods, we were shown a 3D printer. This machine cost 25 thousand dollars, and was slow and expensive to operate. We were allowed to print just one tiny part as part of the class.

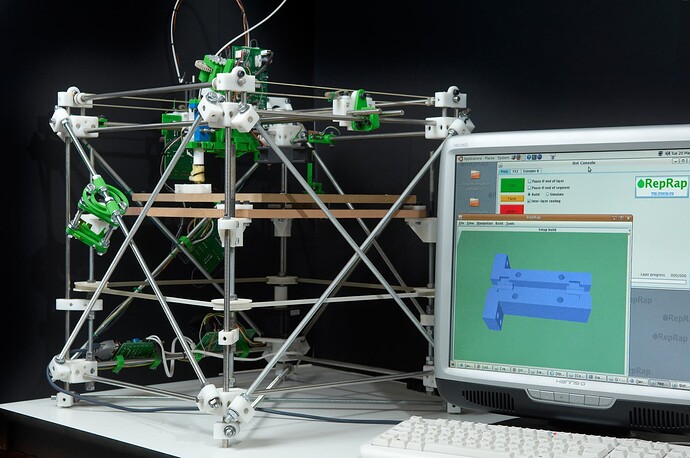

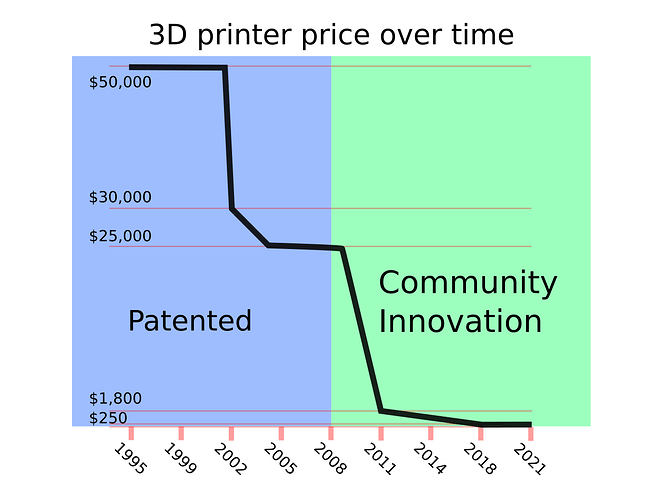

I found the machine fascinating, but the high price kept them out of reach of all but the best-funded organizations. Then, in 2008, the patents for this method of 3D printing expired. Developers in Europe had anticipated this transition, and had designed a machine that cost just a few thousand dollars and could print its own parts.

Within a few years, more machines appeared from hackers in New York, San Francisco, Prague, and elsewhere.

At this point I was working as a Mechanical Engineer, designing parts and programming CNC machines that cut parts out of metal. Operating a CNC machine is serious work, requiring a great deal of skill, materials, and tools. I watched as home brew 3D printers began to mature. These machines offered a real opportunity to start making my own parts at home without complex programming or expensive tools.

I attended the Silicon Valley 3D printer meetups and saw home-made 3D printers in person for the first time. Once a week these nerds lugged their contraptions to a local hackerspace to share what they had been working on, swap tips on how to get things working, and generally commiserate on the difficulties of creating something as bleeding edge as those machines.

Meetups like this were happening all over the world, coordinated over email lists where anyone could log on and share their ideas, designs, and progress. Out of these communities sprang a new generation of machines, more reliable than earlier models.

By 2011 the commercial kits had improved, and I ordered one for myself. I painted my machine green, called it Kermit, and brought it with pride to the meetups. Over the next few years I would install many community upgrades to the machine, and even design and shared my own mods.

It was during this time that I began to see how open source hardware allows many people to contribute good ideas. There were commercial 3D printer manufacturers who sold open source machines, and there were thousands of users who would design their own upgrades. As the manufacturers released new models, they would incorporate many community upgrades.

Open source, by the way, means that all of the design files are freely shared. Anyone is able to copy, modify, and re-share their own versions of the files. They can produce and sell their own robots made from these designs. In this way, a design can grow organically over time.

For the first thirteen years of 3D printing, only one company was allowed to produce the machines. But once the patents expired, a community of thousands of designers and manufacturers the world over was born. These creators found new ways to lower costs and improve functionality. Ten years after the patents expired, the price dropped from $25,000 to $250.

Volumes increased too. Stratasys says they sold sixteen thousand printers in their first fifteen years. Now one company ships over 9000 open source 3D printers a month. These machines are no longer the domain of cash-flush industrial customers, but accessible to small companies and budding engineers the world over.

This point was really driven home for me in 2018, when I flew to the other side of the world to teach a week-long robotics class in Mauritius, an island nation off the East coast of Africa near Madagascar. I coordinated with a local instructor who was able to buy a brand new 3D printer before my arrival from a local Facebook 3D printing group. On this island nation, someone was importing open source 3D printer kits from China, assembling and testing them, and selling them to local hobbyists.

And with that I was able to help new engineers see how their work could go from 3D models to reality in the course of an afternoon.

That was the moment that I really saw how powerful community collaboration was. These students would never be able to access twenty five thousand dollar machines. Community collaboration brought down the price 100 fold and increased access the world over.

In the years since that fateful trip, I began to wonder what would happen if all of our vital machines were open source. Perhaps we would benefit from open source cars, washing machines, and medical equipment.

So when Daniel and I met, I shared with him this story and we agreed to try it. Is it really possible to lower the cost of machines through open source collaboration? Can we make farming robots some day as abundant as 3D printers? Can we go from a world where machines like this drop in price from $20,000 to just $2,000 or even less? How would low cost organic farming machines help people the world over? What would it mean for developing nations to choose regenerative organic over chemical intensive conventional farming? How would their waterways and wildlife and people benefit?

There are a lot of investors dropping money on farming robot projects these days. But with that investment comes an expected rate of return that generally requires that designs are secret, and prices are high.

We aim to try something new. To create a donation-supported non-profit to research new technologies and share them with everyone. To publish our work and create educational materials to help anyone build their own machines. We hope one day soon some of our users will become manufacturers, selling their own designs to the public. This wide scale community development will lower hardware costs, making this technology available to everyone the world over.

If we drive this project forward with our organization and maintain momentum for at least 5 more years, I think this would create the critical mass needed to see this new kind of machine take off.

There are examples of engineering projects funded by donations. Blender is an open source 3D modelling program that has grown over the years to become one of the most popular programs in the industry. Through their work as a consistent community resource, Blender has managed to grow their monthly funding base to a whopping 192,000 dollars a month in donations from over 3000 individuals and 35 corporations.

The Godot video game engine has been growing in recent years, now drawing in over 14 thousand dollars a month in donations from over 1600 patrons.

More and more open source projects are sustaining themselves with this kind of donation. And we believe this model is ideal for pushing forward a fully open source farming automation platform, our Precision Farming Rover, to ensure this technology can spread all over the world while maintaining a low machine cost.

To that end, we’ve partnered with the Open Collective Foundation, a non profit fiscal host that is able to accept tax deductible donations on our behalf. Open Collective is a website for transparently managing fund raisers for projects or organizations like ours. They make it very easy to sign up and make individual or monthly donations with just a few clicks.

Maybe you’re someone who just finds all of this interesting and you’d like to chip in five dollars a month. Perhaps you’re a tech worker with a load of RSUs and dreams of your own automated farm, in which case you might consider the 50 or 100 dollar a month levels. For all the farmers and experimenters out there, we could use anything you can send our way. Just click this link to go to our funding page and make your contribution now.

We can also use expertise and ideas on our forum. You can sign up for free at community.twistedfields.com where you can introduce yourself, read existing threads, and share your thoughts. Everyone is welcome. Together we will make this community shine.

If you found this interesting please share this article with your social networks, and submit the link to your favorite blogs (popular blogs often have a tip line for readers to submit interesting links). If you would be interested in our videos, consider subscribing to our youtube channel, and click the bell icon to be notified of new uploads. In future videos we will share details of our new mechanical and electrical designs as we move towards a stable kit design. We’ve got a few more videos on this channel you may find interesting, so do look around and see what catches your interest.

And don’t forget to visit our Open Collective page and make your donation today.

Thank you so much for reading about our project, and thank you to all of our contributors who are making this project happen.